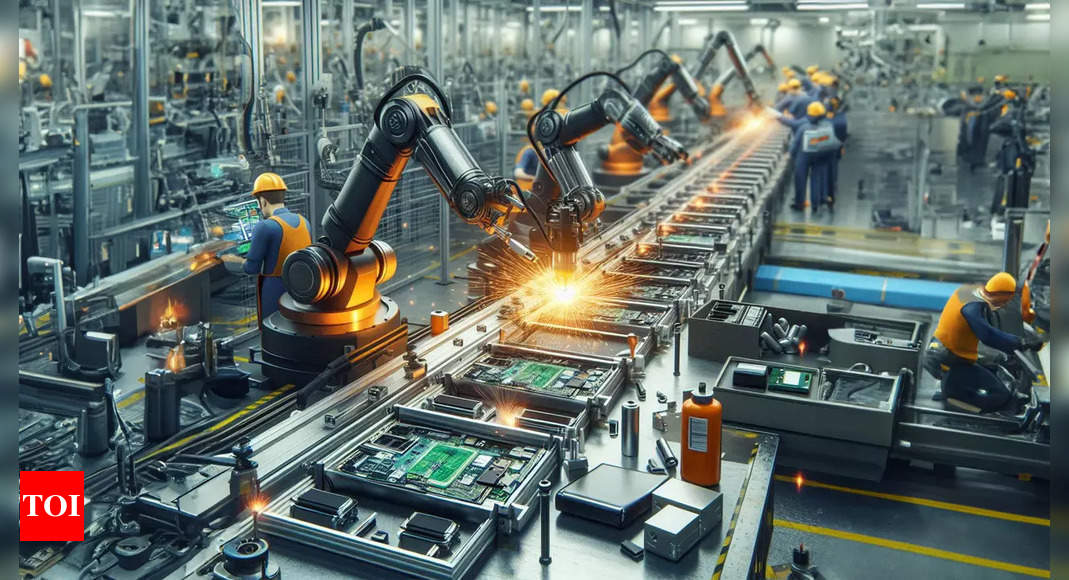

These machines can be utilized in the production lines of contract manufacturers working for global companies like Apple.This move is expected to provide a crucial impetus to the government’s target of $300 billion in electronics exports by 2025.

A person familiar with the developments told the financial daily, “The Tata Group is testing these machines in a staged manner at their Hosur facility.” The objective is to grow more of its local capability, as the company aims to develop the ecosystem in the country, rather than just building enclosures. These machines are one of the many inputs that go into making a component or an enclosure, and the company is looking to reduce its exclusive dependence on certain parts.

Tata Group plans

Experts believe that this development could be a significant boost to the Indian manufacturing story, as it showcases the country’s ability to produce complex machinery and reduce reliance on imports.

Ajai Chowdhry, the co-founder of HCL, emphasized the high demand for casings in the electronics industry. He stated, “Everybody wants casings. If Tata Group is able to do import substitution and they’re able to make these machines in India, it will create an industry because so many people want casings. Anybody who wants to make a phone or a tablet in India needs casings and if they’re able to adhere to Apple’s stringent standards, it would be a high-quality machine in itself.”

According to a source, Indian manufacturers possess varying levels of capability and readiness to implement the plan. This initiative is part of the company’s global strategy to decrease reliance on specific low-tech components before transitioning to more intricate parts. The objective is to diversify and mitigate risks associated with global supply chain disruptions while simultaneously fostering the manufacturing ecosystem within the country.

Also Read | 5 lakh ‘Apployments’: Apple ecosystem to create huge number of jobs in 3 years; iPhone maker may move half its supply chain from China to India

The source mentioned that although Computer Numerical Control (CNC) machines are widely used across various sectors in India, domestic manufacturers currently lack the capability to utilize CNC machines for precision components.

The person stated that diversifying and de-risking the supply chain is a priority for all stakeholders, including the government, manufacturers like the Tata Group, and the companies themselves. An official disclosed that the Tata Group operates approximately 40 lines at their facility in Hosur.

The Tata Group has formed partnerships with two companies, one located in Pune and the other in Bengaluru, an official said.

Although the Tata Group has intentions to export, it may require some time before this plan becomes a reality on the ground, according to one of the sources.

Also Read | Apple Awas Yojana? Apple ecosystem to now build residential facilities for workers after creating 1.5 lakh direct jobs

“It’s a maturity curve,” he explained. “India has a while to go before the export happens. First, the Tata Group must be able to make them good enough for them to use. A lot of machines from India do go overseas, but this one again is about precision stuff, which is so complicated, so it’s a maturity curve that will take time.”

Pankaj Mohindroo, the chairman of the industry body India Cellular & Electronics Association (ICEA), emphasized the significance of developing key capital goods for the industry. He stated, “We are working on developing India as a major assembling and components hub for electronics’ capital goods.”